- support@husseinkey.com

- livechat

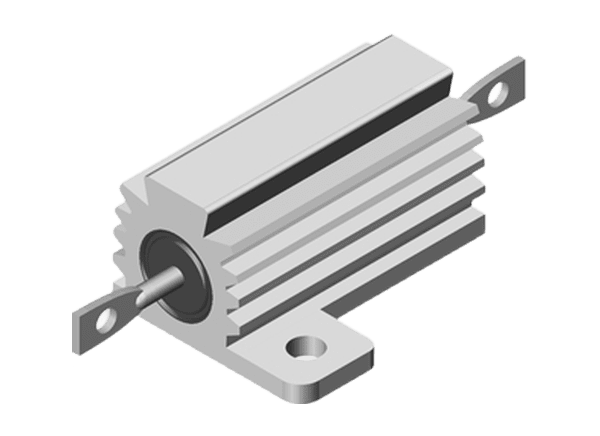

Vishay / Dale RH and NH Chassis Mount Industrial Wirewound Resistors are aluminum housed resistors that are completely welded and molded for total environmental protection. The fixed RH and NH resistors are available in a 0.01Ω to 273KΩ resistance range with seven tolerance options: ±0.05%, ±0.1%, ±0.25%, ±0.5%, ±1%, ±3%, and ±5%. Power ratings range from 7.5W to 250W with operation from -55°C up to +250°C. The NH components are a non-inductive style with Ayrton-Perry winding.