- support@husseinkey.com

- livechat

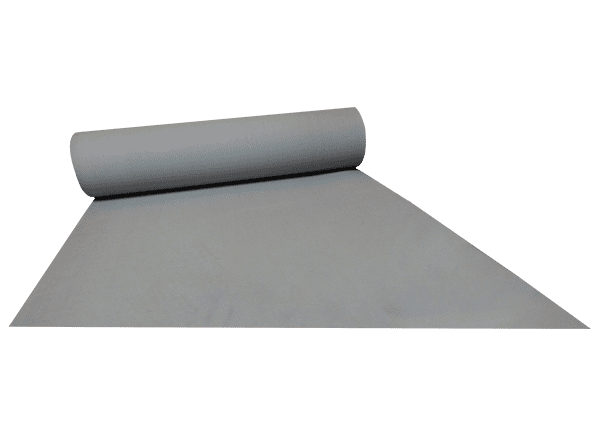

TE Connectivity’s (TE) Kemtron Oriented Wire is a flat sheet material designed for shielding against radio frequency interference (RFI), electromagnetic interference (EMI), and electromagnetic pulse (EMP). Each sheet contains thousands of embedded thin monel or aluminum wires that are perpendicular to the surface. The wires are chemically bonded to silicone or fluorosilicone and crimped to form a slight zigzag, so they do not drastically affect the compression forces required to make a seal. The elastomer provides the environmental sealing component, while the wires offer electrical grounding and shielding. Under the recommended 15% to 20% compression, the wires bite into the mating surface and penetrate through thin oxide layers, providing low contact resistance.

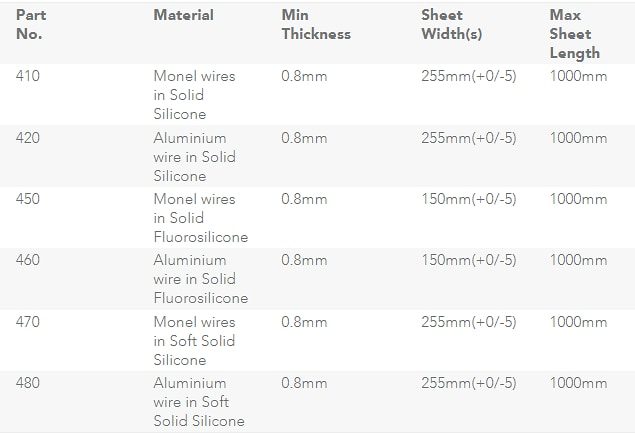

These oriented wire gaskets are available in three material groups:

• 410/420 grades are 40 Shore A solid silicone with monel / aluminum wires for applications where higher compression forces allow for better environmental sealing.

• 450/460 grades are 50 Shore A solid fluorosilicone with monel / aluminum wires for environments where fuels, oils, hydraulic fluids, and other contaminants are present.

• 470/480 grades are 20 Shore A soft silicone with monel / aluminum wires for applications that require lower compression forces.

TE Kemtron Oriented Wire is available in widths of 150mm and 225mm with thicknesses of 0.8mm, 1.6mm, and 2.4mm. The wire options provide flexibility and enable designers to select the ideal product for an application’s galvanic compatibility requirements.