- support@husseinkey.com

- livechat

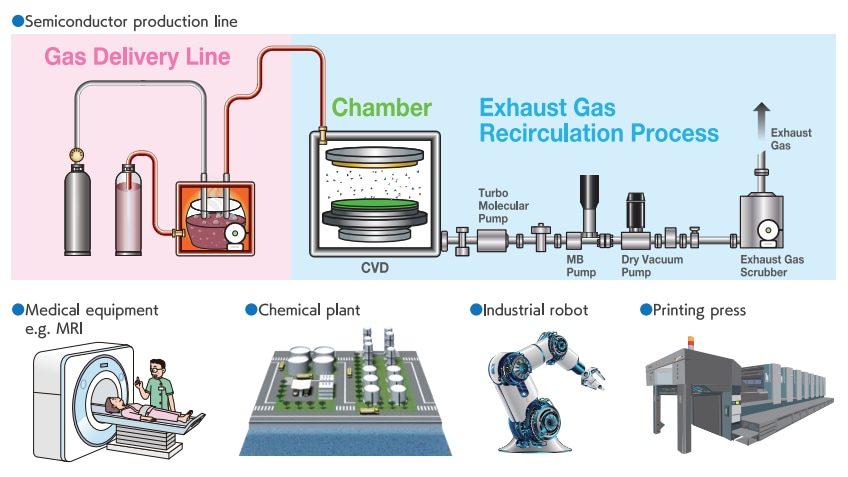

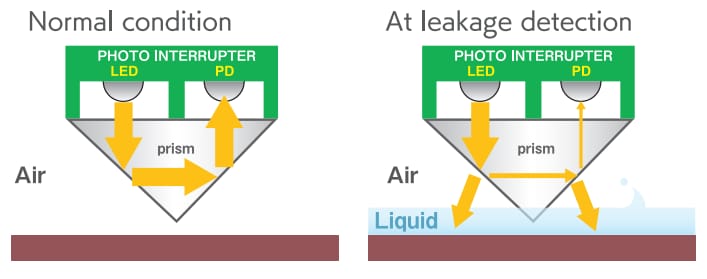

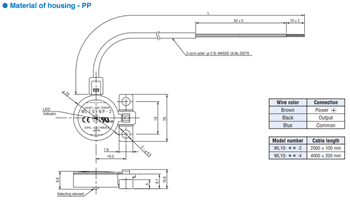

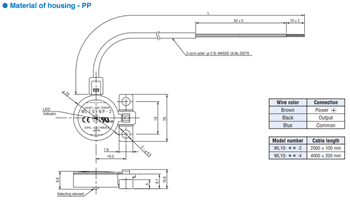

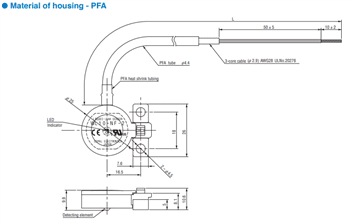

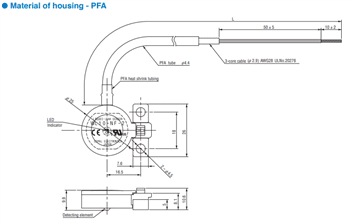

Nidec Components WL10 Liquid Leak Sensors can detect leakage without a douser and additional amplifying circuit. The WL10 sensors include an LED and a partial discharge (PD) detector inside. The light emitted from the LED is reflected by the prism, received by the PD, and converted to current. Nidec WL10 Liquid Leak Sensors feature PFA casing available for detecting leakage of corrosive liquid and are operable in various areas by unique optical technology. This optical technology does not require a douser and detects liquid leakage with high precision and quickness. The liquid leak sensors operate from 12VDC to 24VDC supply voltage range and -10°C to +60°C temperature range. Typical applications include semiconductor production lines, industrial equipment, pneumatic equipment, medical devices, and analyzers.