- support@husseinkey.com

- livechat

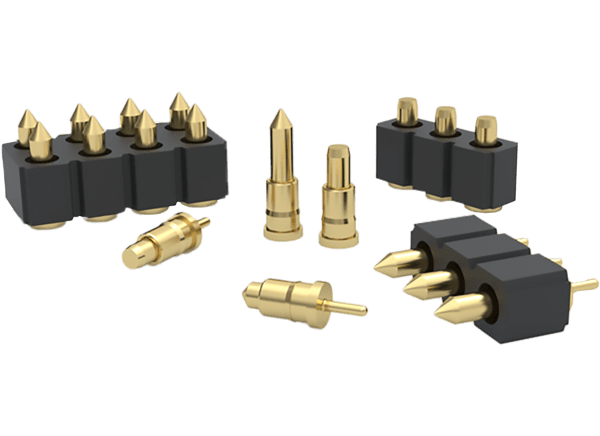

Mill-Max Flat and Pointed Tip Spring-Loaded Pins and Connectors provide solutions for testing and other specialized connection requirements. These spring-loaded components are available with flat- or pointed-tip style plungers. Both styles are available in surface-mount and through-hole terminations with a wide range of initial heights and options for stroke. These pins are constructed with precision machined components and beryllium copper springs. The gold plating ensures conductivity, corrosion resistance, and durability.

The pointed-tip plunger design is often used with spring-loaded pins in test environments. This pointed design concentrates the force, resulting in increased pressure to penetrate oxides or other contaminants on the surface of the test unit. This provides a high-quality, low-resistance connection. Additional uses for the pointed tip plungers include probing or contacting holes or via holes on printed circuit boards. The point offers a more suitable fit than a radius and is suitable for a range of hole sizes.

The flat-tip plungers have a greater surface area at the point of connection, which distributes the electrical charge for more efficient heat dissipation. These plungers also allow for higher tolerance misalignment with mating surfaces. The flat-tip plungers are an ideal solution for applications where the spring pin tip makes contact with round component leads.

Mill-Max Flat and Pointed Tip Spring-Loaded Pins and Connectors meet all the electrical, mechanical, and environmental specifications of their equivalent full radius style pins.