- support@husseinkey.com

- livechat

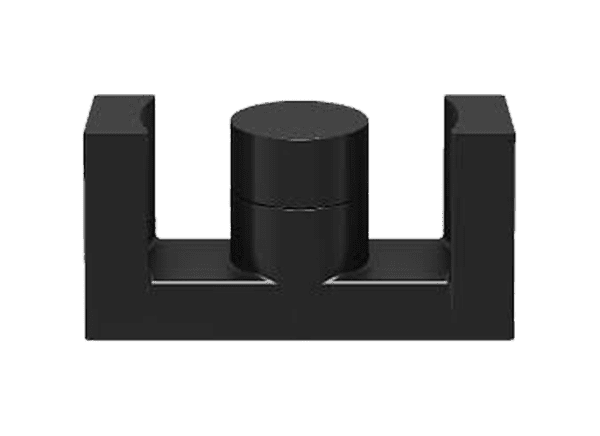

EPCOS / TDK Distributed Gapped Cores increase power handling capability and allow higher currents. These devices are commonly used to design power chokes and flyback converters and reduce proximity losses by up to 70%. These air gaps offer a technical solution designed to significantly lower the fringing flux effect to decrease electromagnetic emissions and heating. EPCOS / TDK Distributed Gapped Cores improve the thermal performance of solid wire and high-frequency (HF) Litz wire designs. The air gaps allow the reduction of the core size by one class (such as E 65 to E 55) thanks to lower winding losses. These EPCOS / TDK cores are designed for the market trends of downsizing and increased power density, making them ideal for automotive and industrial applications.