- support@husseinkey.com

- livechat

TDK provides the CLT32 series power inductors with extremely compact dimensions and excellent electrical values due to their design. These inductors cover an inductance range of 17nH to 440nH and are designed for 13.5A to 60A saturation currents. CLT32 series inductors feature a small footprint of 3.2mm x 2.5mm and an insertion height of 2.5mm and are constructed for a temperature range of -40°C to +165°C, including self-heating.

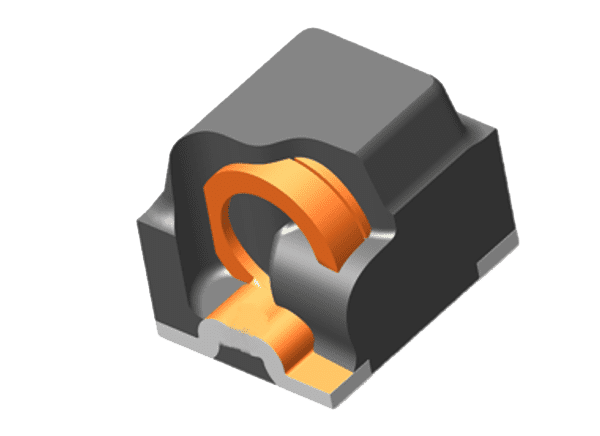

These AEC-Q200-certified components are designed with a solid copper coil over-molded with a ferromagnetic plastic compound. The coil ends function as terminals, significantly increasing reliability – especially for automotive applications. Due to the solid copper coil, these products can achieve an exceptionally low RDC value, keeping losses to a minimum, i.e., when the inductance value is 17nH, the resistance rating is 0.39mΩ.

The compact and highly robust CLT32 inductors are suitable for safety-critical automotive applications in ADAS/AD. High-performance processors used in these fields require currents in the double-digit ampere range. Power Management ICs (PMICs) are used as power supplies that provide these high currents, meaning power inductors for stabilization are key components at the outputs. TDK CLT32 series is designed for switching frequencies up to 10MHz and meets future requirements placed on DC/DC converters with high clock rates.

Q. What are the strong points of CLT32 compared to conventional inductor technologies?

A. The CLT32 has a robust copper structure with no internal connections. The molded body is the core and housing in one unit. So this new inductor offers extremely high reliability.

Q. Why should I use the CLT32 instead of other power inductor series?

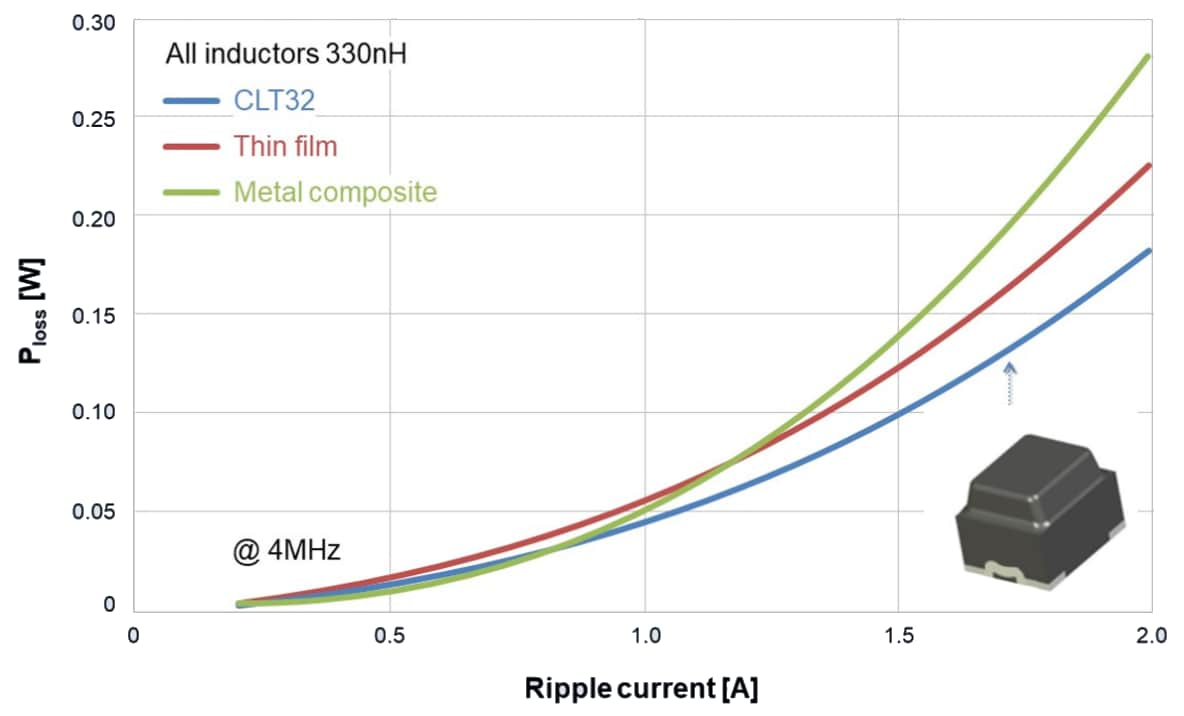

A. CLT32 has an outstanding power density, which means in case of space limitation it is the perfect solution. And, because of its low AC-losses it allows higher ripple currents which can enable lower capacitance values in DC/DC converters. Overall CLT32 can help to reduce system costs.

Q. What properties characterize the magnetic molding compound?

A. It is a completely newly developed ferromagnetic plastic compound. Particularly noteworthy are the low core losses, the excellent electrical properties even at high frequencies, and the high-temperature range. In addition, the material can be processed with low pressure and low temperature, which avoids unwanted stress on the coil during production.

Q. Will there be other CLT sizes?

A. Other case sizes are under development.