- support@husseinkey.com

- livechat

Allegro MicroSystems ACS72981 High-Precision Linear Hall-Effect-Based Current Sensor ICs are economical and precise AC or DC sensing solutions. The ACS72981 features a 250kHz bandwidth ideal for motor control, load detection and management, power supply and DC-to-DC converter control, and inverter control. Additionally, the <2μs response time enables overcurrent fault detection in safety-critical applications.

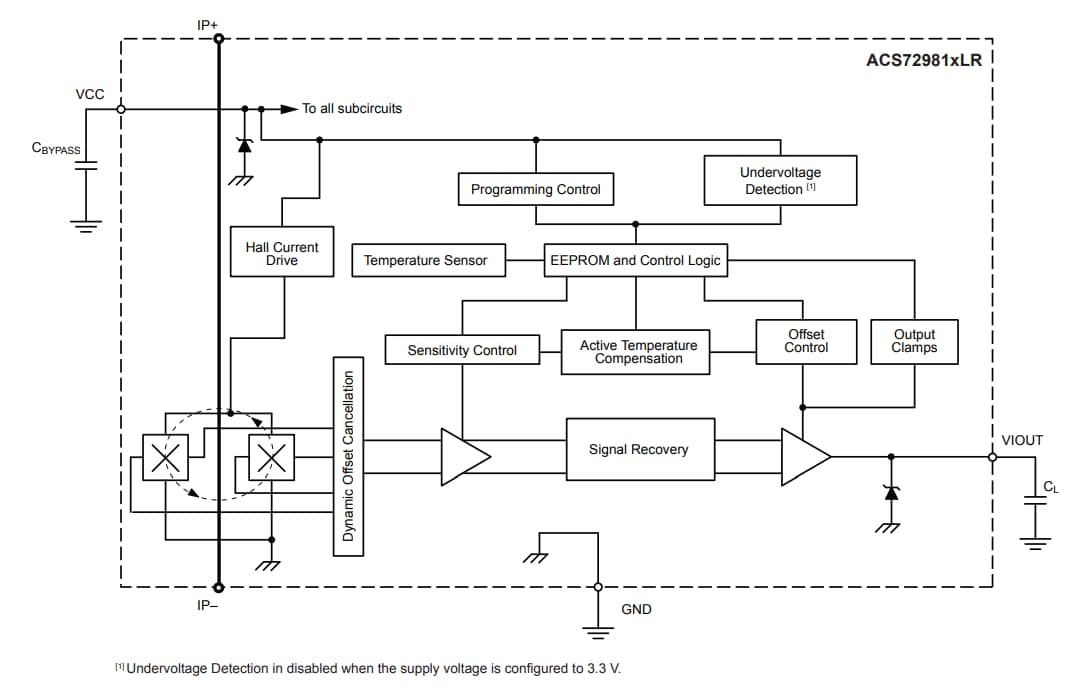

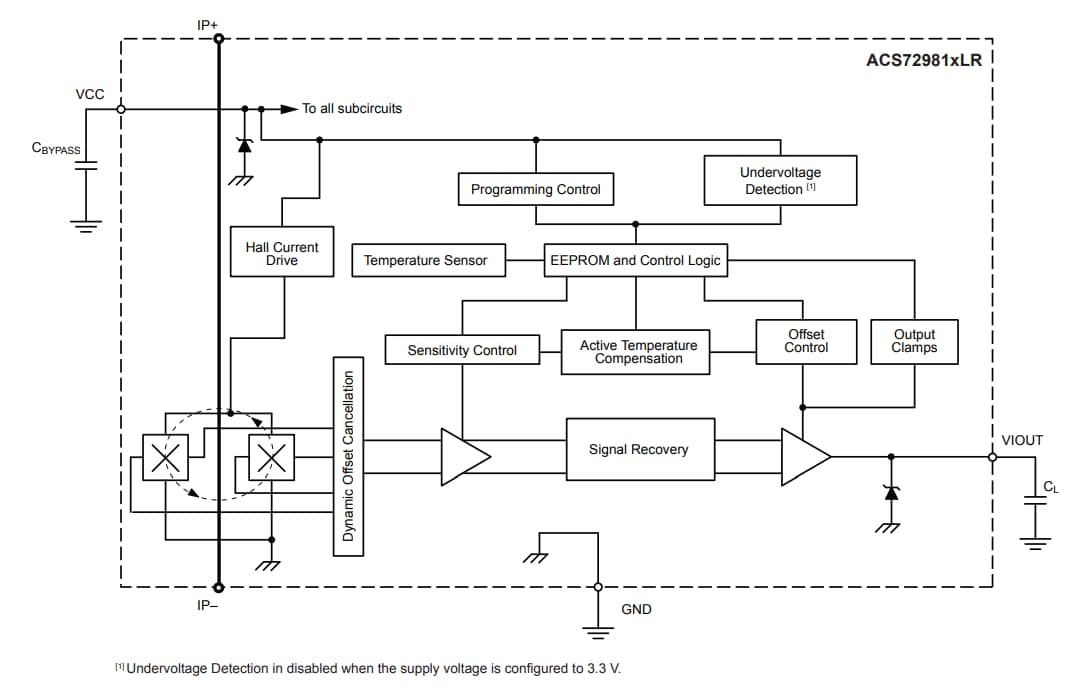

Allegro MicroSystems ACS72981 Linear Hall-Effect Current Sensor ICs combine a precision, low-offset linear Hall circuit with a copper conduction path near the die. Applied current flows through the copper conduction path and generates a magnetic field which the Hall IC converts into a proportional voltage. The close proximity of the magnetic signal to the hall transducer optimizes the device’s accuracy. The low-offset, chopper-stabilized BiCMOS Hall IC supports a precise, proportional output voltage, which is pre-programmed for accuracy. Proprietary digital temperature compensation technology dramatically improves the zero output voltage and output sensitivity accuracy over temperature and lifetime.

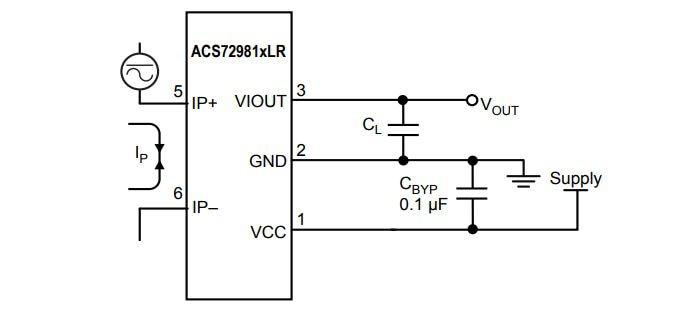

The output of the device increases when current flows through the primary copper conduction path (from terminal 5 to terminal 6), which is the path used for current sampling. The internal resistance of this conductive path is 200μΩ typical, providing low power loss and increasing power density in the application. The sensor employs differential sensing techniques that virtually eliminate output disturbance due to the common-mode interfering magnetic field.

The copper conductor’s thickness allows the device’s survival at high overcurrent conditions. The terminals of the conductive path are electrically isolated from the signal leads (pins 1 through 3). The device is fully calibrated and supports 5V or 3.3V power supplies. The ACS72981 has a heavy gauge lead frame made of oxygen-free copper.