- support@husseinkey.com

- livechat

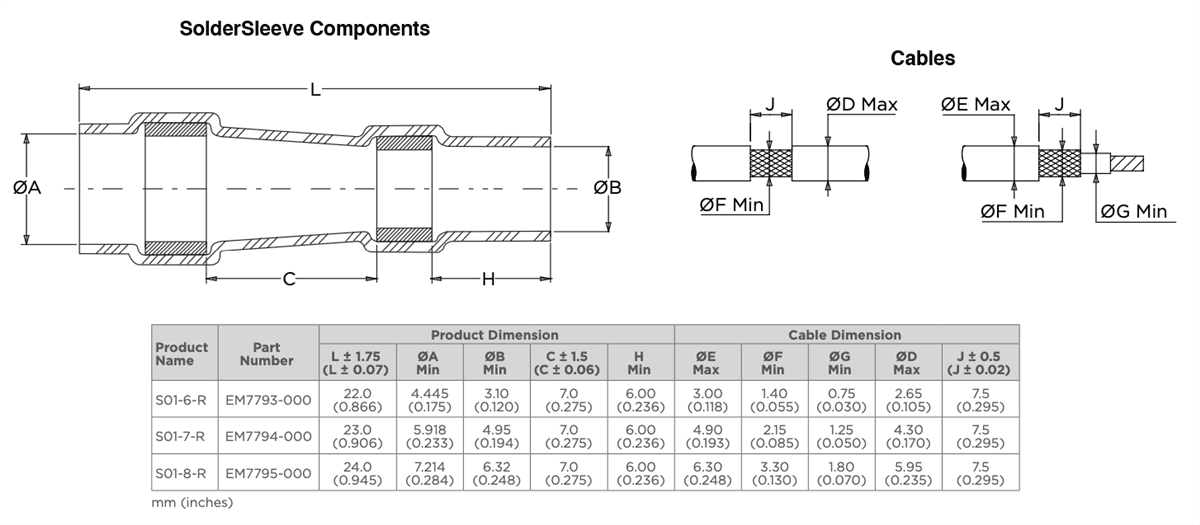

TE Connectivity SolderSleeve Devices for Space Applications provide low outgassing and resistance to extreme temperatures to support critical space industry requirements. The transparent blue SolderSleeve components offer reduced size, weight, and power (SWaP), environmentally protected shield terminations on cables, insulation, protection, and strain relief. Flux-free solder leaves no trace particles post-installation, and the sealing rings ensure the installation remains intact. These features address the need for zero foreign object damage (FOD) levels in demanding space industry solutions. TE Connectivity SolderSleeve Devices can be used for silver-plated cables with a +150°C jacket rating and installed with standard TE tools.