- support@husseinkey.com

- livechat

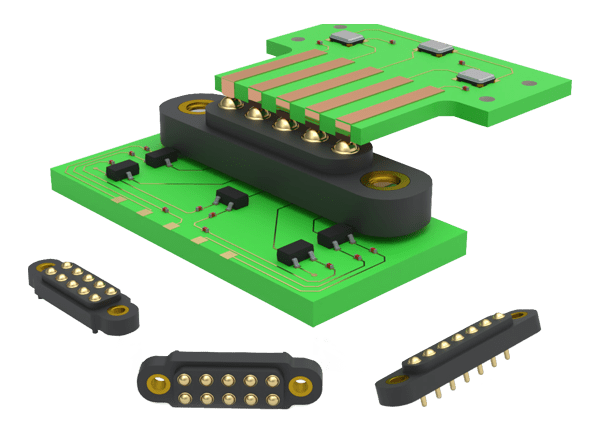

Mill-Max Omniball® Spring-Loaded Connectors are designed for applications requiring multiple contact points in sliding or rotational orientations. The unique Omniball® spring-loaded contacts (spring-loaded pins in which the traditional plunger has been replaced by a gold-plated, brass ball), feature a rolling ball interface, enabling contact to be made between components in axial and non-axial alignments. These versatile connectors facilitate creative solutions for innovative interconnect arrangements while providing optimal electrical, mechanical, and structural reliability.

The Omniball® Spring-Loaded Connectors optimize connections between components that slide or revolve into contact. When engaged, the ball compresses and rolls, allowing the mating surfaces to make contact and then easily slide parallel to each other while spring force ensures consistent electrical connection is maintained. This rolling action prevents binding, premature wearing, and structural failure that traditional, plunger-style spring pin connectors are prone to.

Omniball® connectors, offered in single and double row configurations, feature a 4mm (0.1575″) pin-to-pin spacing, a 6.76mm (0.266″) above board height, and are available in through-hole or surface-mount termination styles. There are options for threaded inserts to provide secure mounting in rugged applications and for alignment pegs on the SMT connectors. The Nylon 4/6 insulator material provides excellent high-temperature performance, dielectric strength, and mechanical toughness. Omniball® contacts feature a 0.762mm (0.030″) maximum stroke, gold plating on all components, and a ø2.3mm (ø0.091″) ball interface. These spring-loaded pins are durable and have been tested to 1,000,000 compression cycles and rolled over 67 miles (108km) at half stroke while still meeting specifications for contact resistance of 30mΩ with a spring force of 55 grams at mid-stroke {0.381mm (0.015″)]. Single row connectors are offered in 2 to 10 positions and double row connectors are offered in 4 to 20 positions.

The Mill-Max Omniball® Spring-Loaded Connectors are an excellent choice for any application that involves sliding or rotating connections, such as: “twist and lock” cable connectors; docking stations; rack/server drawers; quick connect, and blind mating applications. Mounting options include vertical or horizontal orientations and these connectors can be used to eliminate cables where circuit board to bus bar connections are made in tight spaces.