- support@husseinkey.com

- livechat

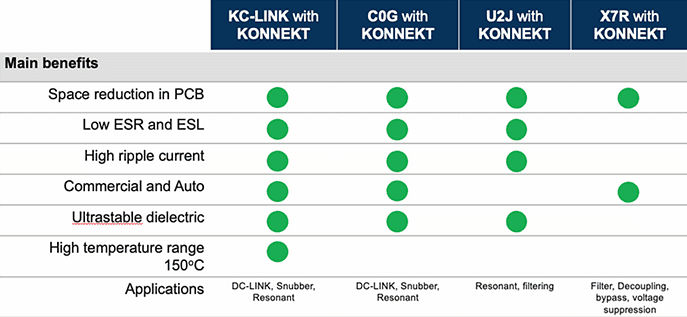

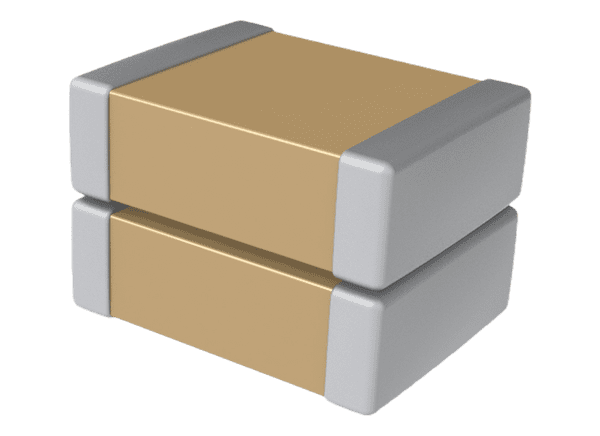

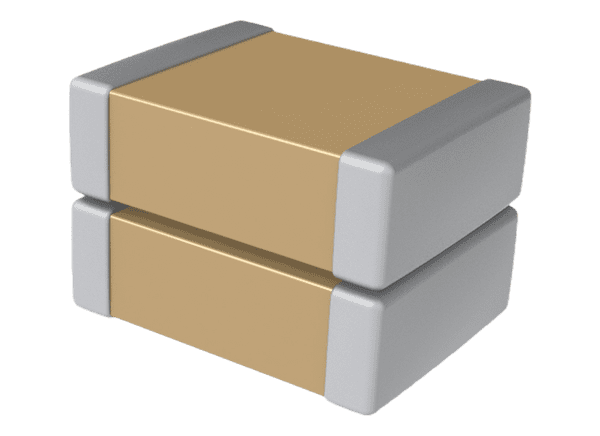

KEMET KONNEKT™ High-Density Packaging Technology enables components to be bonded together without the use of metal frames, reducing with it the ESR, ESL, and thermal resistance to capacitors. The KEMET KONNEKT technology utilizes innovative transient liquid phase sintering (TLPS) material. The TLPS material has a low-temperature reaction of low melting point metal or alloy, with a high melting point metal or alloy, to form a reacted metal matrix. This process results in a highly conductive bonding material that can be used to connect multiple MLCCs together to form a single surface-mountable component.